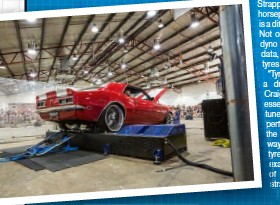

ROLLER DYNOS

“WHAT you’re essentially doing with a roller dyno is putting the car on a treadmill,” Craig says. “They work well in low-to medium horsepower and diesel applications, transferring energy through the tyres to the rollers.”

Placing a vehicle on a roller dyno is a quick and straightforward process, which is why they are most often favoured for dyno competitions, where dozens of vehicles can go on and off a dyno in a single day.

Roller dynos have traditionally been widely favoured by tuning workshops, and while the power and torque figures they provide are subject to the variable of drivetrain loss, one major advantage a chassis dyno has over an engine dyno is that the engine is being run in its real-world environment. In other words, it’s being tested with the very same fuel system, exhaust system, cooling system and accessories it will be used with in the long term, rather than the ‘generic’ fuel pumps and regulators, headers and radiators that are often used on an engine dyno. Not only will a chassis dyno allow the engine to be tuned to suit these components, but it will potentially show up any inadequacies or problems that may exist with the engine’s ancillary systems, and allow for troubleshooting. The major limitation encountered with a roller dyno is tyre loss, and it’s a big one. Strapping today’s modern, highhorsepower street and drag cars is a difficult and often fruitless task. Not only does loss of traction on dyno rollers provide inaccurate data, but it also makes a mess of tyres in a big hurry. “Tyres are the biggest killer from a drivetrain loss perspective,” Craig says. “Repeatability is essential for tuning, because the tuner could be increasing the performance of the engine, but the gains are not making their way through the driveline to the tyres and onto the rollers. For example, you’ll add one degree of ignition timing and see it straight away on an engine dyno, but not necessarily on a roller dyno.

“They don’t work particularly well with soft tyres, and slicks in particular will heat up quickly and increase losses dramatically with each pull,” he continues. “As tyres heat up they absorb energy that isn’t being transferred to the roller. Tyres distort, the circumference of the tyre changes and the contact patch is reduced, resulting in traction loss. All tyres slip a little on a roller dyno, but as long as the tyre slip is consistent and repeatable, it’s fine from a tuning perspective. But the more horsepower you’re dealing with, the greater tyre loss becomes. You can add retarders to a dyno but it won’t help traction, and with anything over 1000hp, you’re generally wasting your time on a roller dyno.”

In a logistical sense, roller dynos are a great thing. They can be configured to be quite portable, require next to no infrastructure, and only require one bay worth of space. You can even park a car on them when they’re not in use.

“You need to bear in mind with roller dynos there are a lot of rotating parts, and there is always a risk of tyre failures or wheel weights coming loose,” Craig says. “Strapping cars to roller dynos is no problem for lower power applications, but a lot more attention needs to be paid to strapping to overcome tyre loss issues in higher power applications, and correctly positioning the car so it transfers energy to the forward rollers.

“Again, the key thing to aim for is repeatability for tuning purposes.”